products

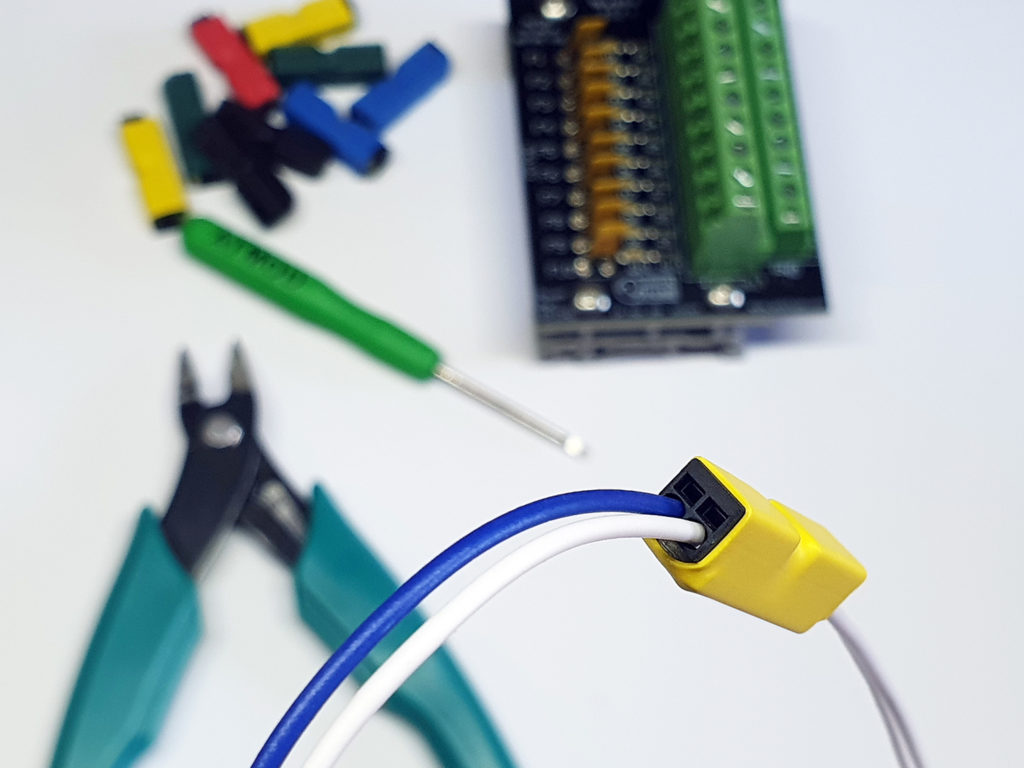

Installing security alarm system End of Line (EOL) resistors has never been faster. Never get your resistors wrong or suffer from broken joins again. Using the ATMOD is as simple as:

- Strip the cables from the alarm device and alarm panel

- Twist and insert the wires into the ATMOD

- Job Done

Gone are the days of fiddly soldering or crimping individual resistors only to have them break or find out your apprentice has installed them all backwards! A new apprentice or even untrained staff can install alarm devices using the ATMOD in a fraction of the time traditionally required.

FEATURES

- Quick-connect, push-in terminals

- Colour coded insulation

- Pre-built PCB with surface mount resistors

- Tab to indicate correct orientation

- Rugged, insulated construction

- Tiny size fits inside alarm devices, door frames and duct

CONFIGURATIONS

- Yellow (ATMOD47) – 4K7/4K7 Resistors | Gallagher, Cardax

- Red (ATMOD10) – 10K/10K Resistors | Tecom, Pacom, CS Technologies

- Green (ATMOD22) – 2K2/2K2 Resistors | Intergriti

- Black (ATMOD01) – 1K/1K Resistors | Lenel, Protégé, Mercury, Genetec, Avigilon, C•Cure

- White (ATMOD18) – 180Ω/300Ω Resistors | PCSC

- Orange (ATMOD2R) – 22K/22K Resistors | Siemens

- Blue (ATMOD68) - 2K2/6K8 Resistors | Concept

- Grey (ATMOD680) - 680Ω/680Ω Resistors | Dormakaba

- Grey/White (ATMOD122) - 1K/2K2 Resistors | CEM

- Brown (ATMOD33) 3K3/3K3 Resistors | Reliance

- Brown/Purple (ATMOD374S) 3K74 Resistor | Reliance

- Brown/Blue (ATMOD698S) 6K98 Resistor | Reliance

- Brown/Black (ATMOD33S) 3K3 Resistor | Reliance/Bosch

- Brown/White (ATMOD68S) 6K8 Resistor | Bosch

- Brown/Orange (ATMOD36) 6K8/3K3 Resistors | Bosch

Other configurations on request.

ATMOD Cost Comparison Calculator

IMPORTANT

Using the ATMOD saves time and therefore labour costs compared to traditional methods.

*Enter your internal labour rate (total cost of a technician) to find out how much the ATMOD can save your business.

You can also adjust the cost of hand built parts, the individual ATMOD cost and the number of devices.

ATMOD install time is estimated at 1 minute, traditional resistor install time is estimated at 5 minutes.