End of line (EOL) resistor circuits are one of the basic building blocks of security and access control systems. Field devices such as reed switches, duress buttons, motion sensors and locks all use EOL circuits to tell the security panel the device state and help to ensure that the cable serving each device is kept secure.

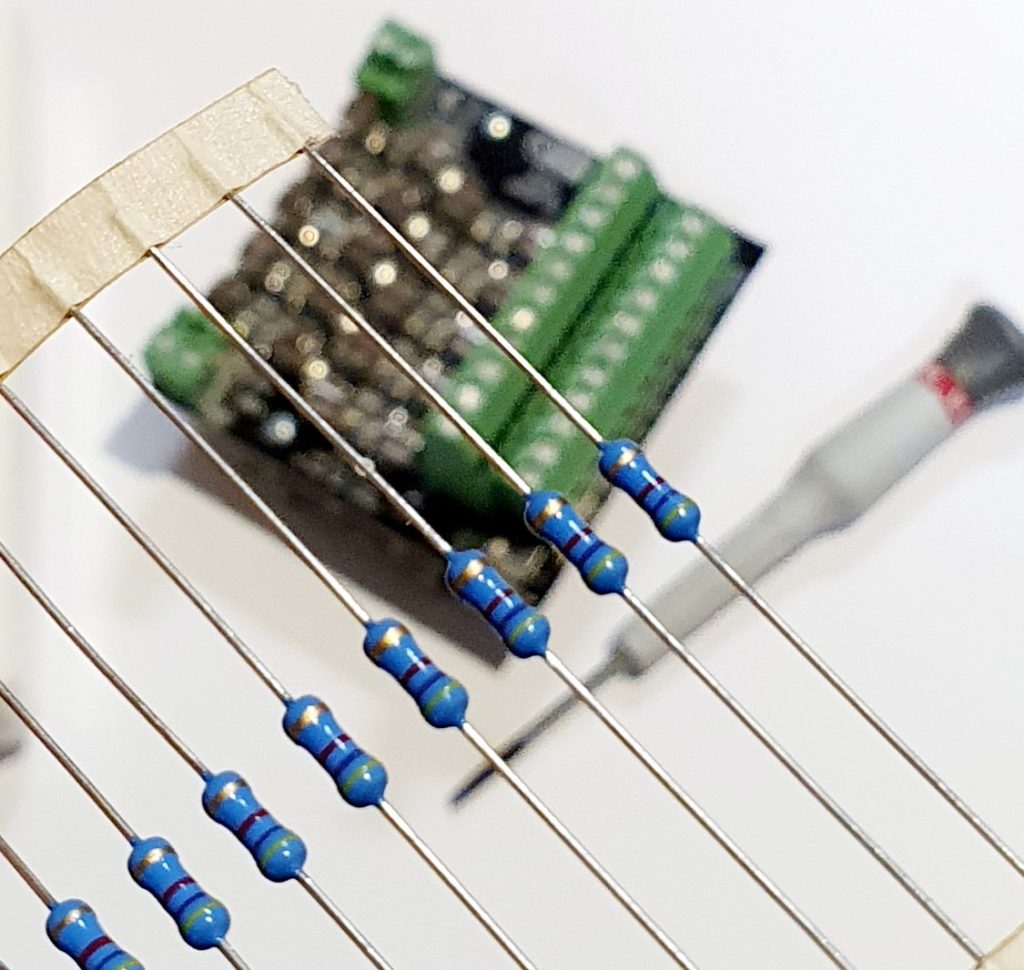

The EOL resistors that come “free” with every security panel add a major vulnerability to security systems. These resistors, supplied on tape, are called “axial” resistors and are designed to be soldered, with strain relief, to a printed circuit board. They were never designed or intended to be used in the field connected directly to cable or security devices.

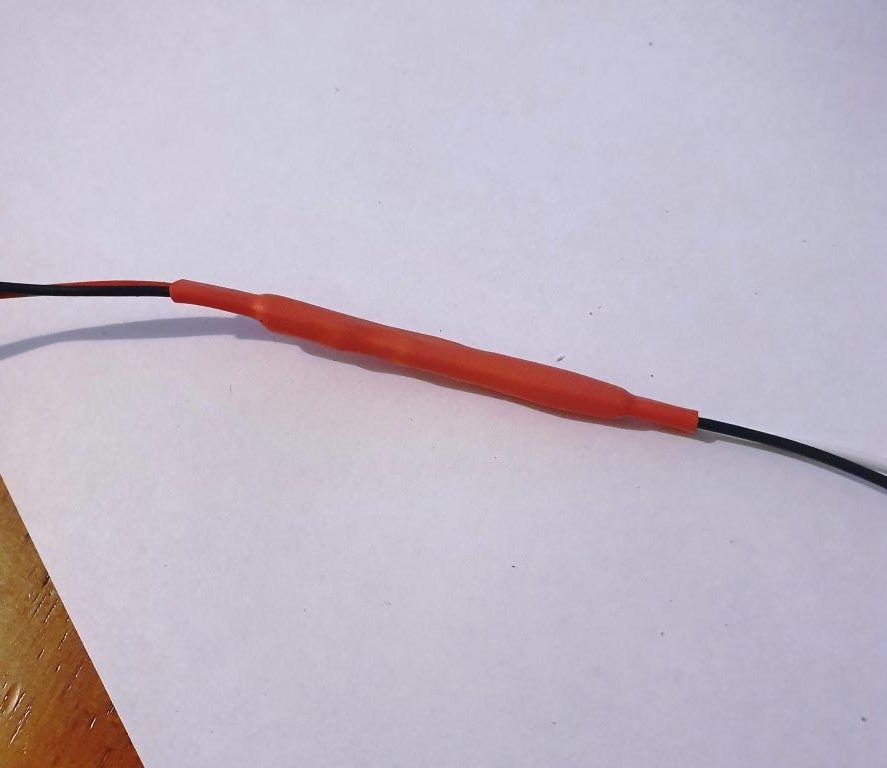

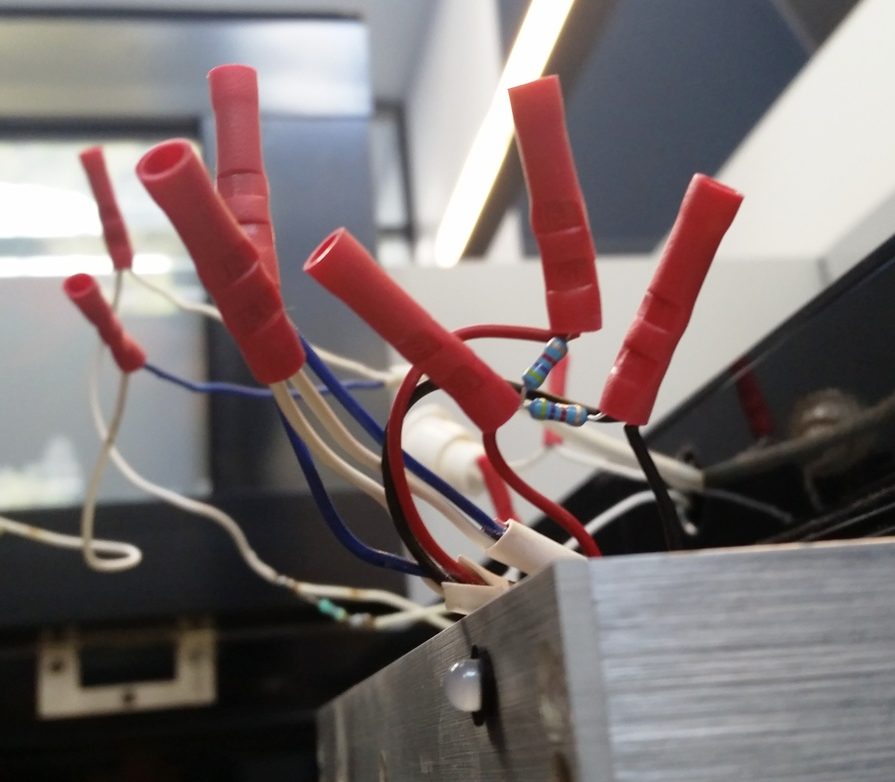

Axial EOL resistors and examples of problematic installations prone to faults.

Axial resistor leads are made from brittle solid copper. They often can’t withstand even the minor strain placed on them when terminated then folded or pushed into a tight door frame, cable duct or wall cavity.

Every security technician has broken EOL resistors at some point and has found broken resistors during service calls. Poor terminations, including broken resistors are one of the leading causes of security system service call-outs and security device downtime.

Building EOL resistors circuits in the field using axial resistors is also fiddly, time-consuming and makes up a large component of labour costs when installing new security devices. One incorrectly made or broken resistor network can take a lot of time to fault-find and repair, quickly eroding profit margin.

Pre-built EOL resistor packs and devices with built-in EOL resistors are widely available in the modern security market. These off-the-shelf solutions eliminate broken resistors and reduce termination errors. Throwing out the axial resistors in preference for a readymade solution will save installers labour costs and security system owners many headaches.